Leading Factors to Pick Specialist Welding Inspection Milwaukee Services

Wiki Article

Recognizing the Value of Welding Examination in Ensuring Structural Stability and Safety Throughout Various Industries

Welding assessment is a vital process that safeguards architectural honesty and safety throughout varied industries. By meticulously analyzing weld high quality, inspectors aid prevent problems that can bring about disastrous failures. This systematic assessment not only reinforces conformity with sector requirements however likewise plays an essential role in protecting assets and making certain public security. The ramifications of disregarding proper inspection techniques are extensive, usually leading to substantial financial and human prices. As we discover the details of welding evaluation, the question emerges: what are the most vital aspects that add to efficient examination processes?Role of Welding Assessment

While the stability of welded frameworks is critical to security and performance, the role of welding examination can not be overstated. Welding evaluation functions as a vital top quality control procedure that ensures the adherence to established standards and specifications throughout the welding operation. By methodically evaluating welds for flaws, inconsistencies, and non-compliance, assessors play a vital role in safeguarding the integrity of structures throughout various markets.Welding assessments incorporate an array of activities, from pre-weld evaluations to post-weld examinations. These evaluations not only determine prospective concerns prior to they rise however likewise boost the overall reliability and life-span of welded parts. Welding Inspection Milwaukee. Inspections help to confirm the ability and proficiencies of welders, guaranteeing that welding treatments are implemented appropriately and products work

In addition, a rigorous inspection method cultivates compliance with regulatory demands and sector criteria, decreasing the threat of disastrous failures. By advertising a culture of safety and security and responsibility, welding examination contributes dramatically to both operational and financial effectiveness. In sum, the duty of welding assessment is important, as it underpins the quality, safety and security, and durability of bonded structures crucial to modern-day facilities and market.

Kinds of Welding Inspections

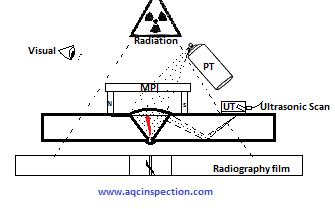

Comprehending the numerous sorts of welding evaluations is crucial for preserving the high quality and safety and security of welded frameworks. Welding examinations can be classified right into numerous kinds, each offering a specific purpose in the assessment process.Aesthetic inspection is the most fundamental type, entailing a mindful assessment of the welds with the naked eye or through magnifying. This technique aids determine surface area problems such as fractures, insufficient fusion, or too much spatter.

Following is non-destructive testing (NDT), which consists of strategies such as ultrasonic testing, radiographic testing, and magnetic particle testing. These methods allow inspectors to examine the honesty of welds without compromising the material's framework. Ultrasonic screening uses high-frequency sound waves to find interior imperfections, while radiographic testing employs X-rays or gamma rays to envision interior weld features. Magnetic bit screening, on the other hand, works for detecting surface area and near-surface suspensions in ferromagnetic products.

Destructive testing, though much less common, involves literally examining examples to comprehend the weld's mechanical properties. Each kind of assessment adds to an extensive evaluation, making certain that welding meets sector requirements and security demands.

Sector Requirements and Laws

Developing industry requirements and policies is essential for guaranteeing the safety and integrity of welded structures. These criteria function as benchmarks for high quality, safety, and performance, leading producers and examiners in the implementation of welding processes. Different organizations, such as the American Welding Culture (AWS) and the International Company you could check here for Standardization (ISO), have established detailed standards that determine procedures for welding methods, credentials of welders, and assessment strategies.Conformity with these laws not just improves the top quality of welds yet also minimizes dangers related to structural failures. Specific codes, such as the ASME Central Heating Boiler and Pressure Vessel Code, outline requirements for the building and construction of stress vessels, ensuring they can withstand functional stresses. In addition, nationwide and local guidelines usually mandate adherence to these sector criteria, enhancing their value throughout industries like building and construction, aerospace, and auto manufacturing.

Routine updates to these criteria mirror innovations in modern technology and welding strategies, making certain that security steps stay relevant. Therefore, a detailed understanding and execution of these standards is important for welding specialists, promoting a culture of safety and quality in bonded structures.

Effects of Poor Inspections

Poor examinations can cause extreme repercussions in the welding industry, undermining the very requirements and policies made to ensure safety and architectural honesty. The effects of poor examinations can show up in numerous types, from instant safety hazards to lasting structural failures. Among one of the most worrying results is the capacity for disastrous crashes, which can lead to considerable injury or loss of life. In industries such as building and construction, manufacturing, and aerospace, the implications of ineffective welding can endanger whole frameworks or elements, causing expensive repair services and comprehensive downtime (Welding Inspection Milwaukee).Moreover, insufficient inspections can taint a business's reputation and cause lawful effects, including fines and litigation. Non-compliance with well-known standards not only threatens the integrity of tasks however likewise reduces customer count on the brand. In addition, the economic ramifications can be incredible, including both straight costs associated with repairs and indirect costs such as lost company opportunities and boosted insurance policy premiums. Inevitably, the ramifications of bad inspections prolong beyond specific jobs, influencing industry-wide requirements and public assumption, therefore emphasizing the vital demand for reliable and extensive welding inspections.

Best Practices for Effective Assessments

Effective welding assessments are vital to ensuring the integrity and security of welded frameworks. To accomplish optimum outcomes, inspectors have click here now to follow a number of best techniques that boost the assessment procedure.

Secondly, assessors ought to possess the essential certifications and certifications relevant to the welding procedures and materials being examined. Recurring training and expert advancement are important to staying upgraded on sector requirements and technical innovations.

Additionally, utilizing proper examination tools and methods, such as visual examinations, ultrasonic testing, and radiographic analyses, is important for detecting problems that can jeopardize architectural honesty.

Lastly, thorough documents of the inspection procedure is necessary. This includes recording searchings for, photos, and any corrective actions taken. Clear and exact coverage not only facilitates liability yet likewise aids in future examinations and maintenance. By carrying out these best techniques, organizations can significantly boost the effectiveness of their welding inspections and make certain risk-free, reputable operations.

Conclusion

In verdict, welding evaluation is vital for preserving structural integrity and security throughout different industries. Focusing on efficient welding assessments is crucial to guarantee the safety and security of workers, properties, and overall operational integrity.

As we explore the complexities of welding examination, the inquiry emerges: what are the most vital variables that contribute to efficient assessment procedures?

Welding evaluation offers as a crucial high quality control procedure that guarantees the adherence to developed criteria and requirements throughout the welding procedure. In sum, the duty of welding evaluation is essential, as it underpins the quality, safety, and durability of bonded frameworks important to modern-day infrastructure and sector.

Numerous organizations, such as the American Welding Society (AWS) and the International Company for Standardization (ISO), have actually established comprehensive standards that determine procedures for welding techniques, qualification of welders, and examination techniques.

Inevitably, the ramifications redirected here of inadequate assessments expand beyond specific tasks, influencing industry-wide requirements and public understanding, therefore highlighting the essential need for rigorous and efficient welding evaluations.

Report this wiki page